- Industrial Centrifugal Water Pumps

- Types Of Casing In Centrifugal Pump Pdf

- Pump Types And Operation Pdf

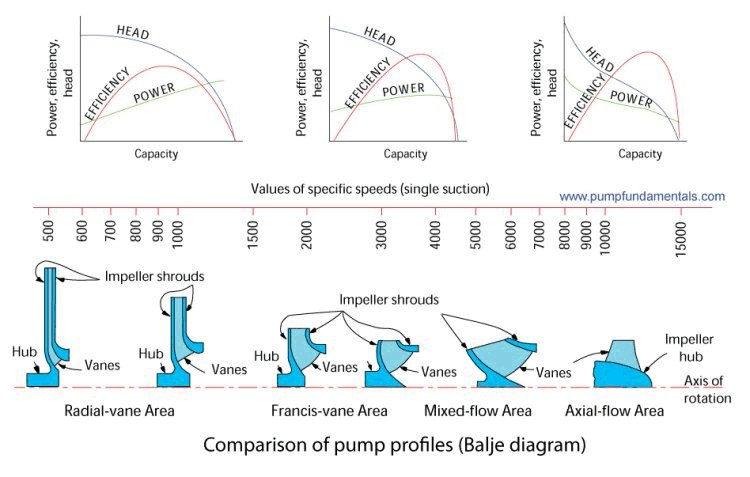

There are four main type classifications of centrifugal pump, with the chief distinction of each being the mechanism that drives the reciprocating diaphragm. Mechanically Actuated. This type of pump has a reciprocating mechanical linkage that is directly attached to the diaphragm. Types of Centrifugal Pumps and how they work including Long-Coupled, Close-Coupled, Self-Priming, Straight, Multi-Stage, Types of Centrifugal Transfer & Sprayer Pumps & more. Centrifugal pump are typically used for large discharge through smaller heads. Centrifugal pump are often associated with the radial-flow type. However, the term 'centrifugal pump' can be used to describe all impeller type rotodynamic pumps including the radial, axial and mixed-flow variations. 3.4 TYPES OF ROTODYNAMIC FLOW PUMP.

PDF Centrifugal Pump Handbook By Sulzer Pumps Limited Book Free Download. Enables readers to understand, specify and utilise centrifugal pumps more effectively, drawing on the industry-leading experience of Sulzer Pumps, one of the world’s major centrifugal pump developers. Covers theory, design and operation.

Types of centrifugal pumps. Centrifugal pumps can be classified into several types depending on factors such as design, construction, application, service, compliance with a national or industry standard, etc. Therefore, one specific pump can belong to different groups and at times pump is known by its description itself. This is all about centrifugal pump principle, construction, working, types, advantages, disadvantages with its application. If you have any query regarding this article, ask by commenting. If you like this article, don’t forget to share it on social networks. Subscribe our website for more informative articles. As you can see from figure 2, centrifugal pumps can be categorised in different groups: Radial flow pumps, mixed flow pumps and axial flow pumps. Radial flow pumps and Semi-axial flow pumps are the most common types used. Different demands on a centrifugal pump’s performance, especially with regard to head, flow, and installation, together with demands for economical operation, are only a few of the reasons why so many types of pump exist.

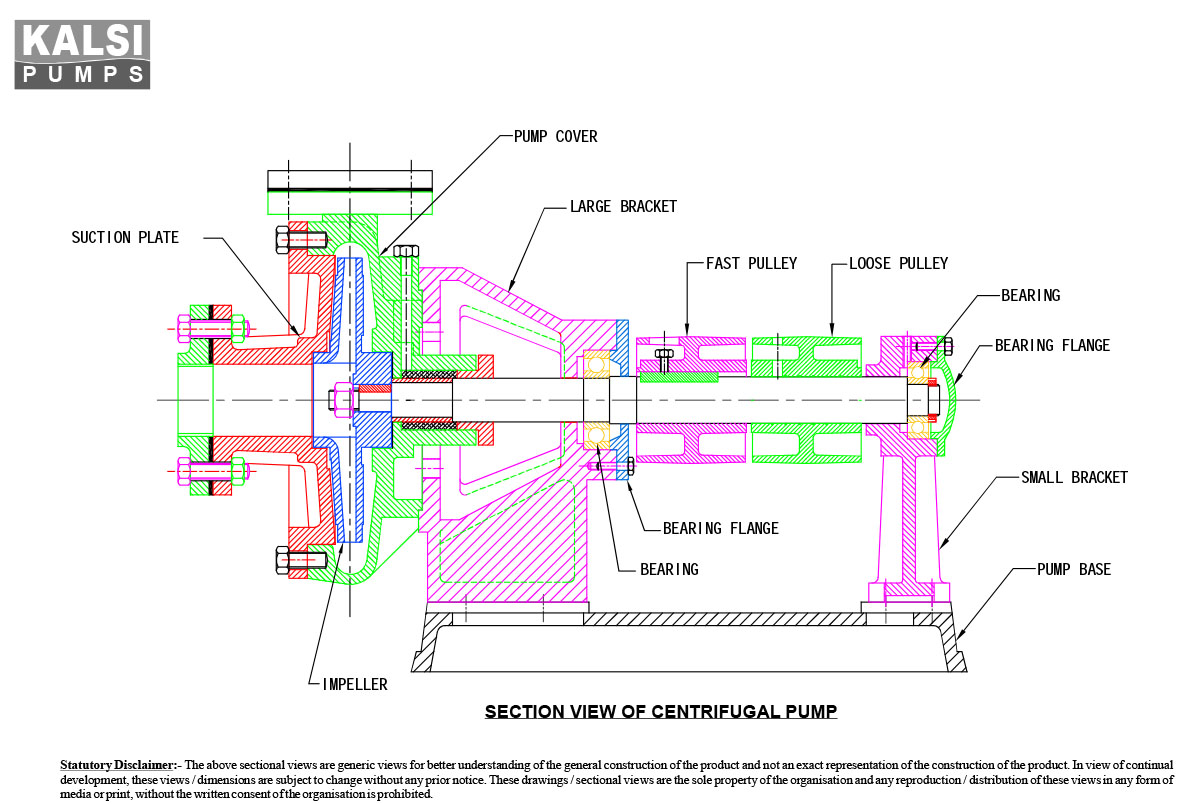

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery.[1] The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits.

Common uses include water, sewage, agriculture, petroleum and petrochemical pumping. Centrifugal pumps are often chosen for their high flow rate capabilities, abrasive solution compatibility, mixing potential, as well as their relatively simple engineering.[2] A centrifugal fan is commonly used to implement a vacuum cleaner. The reverse function of the centrifugal pump is a water turbine converting potential energy of water pressure into mechanical rotational energy.

- 2How it works

- 2.1Description by Euler

- 10Priming

History[edit]

According to Reti, the first machine that could be characterized as a centrifugal pump was a mud lifting machine which appeared as early as 1475 in a treatise by the Italian Renaissance engineer Francesco di Giorgio Martini.[3] True centrifugal pumps were not developed until the late 17th century, when Denis Papin built one using straight vanes. The curved vane was introduced by British inventor John Appold in 1851.

How it works[edit]

Like most pumps, a centrifugal pump converts rotational energy, often from a motor, to energy in a moving fluid. A portion of the energy goes into kinetic energy of the fluid. Fluid enters axially through eye of the casing, is caught up in the impeller blades, and is whirled tangentially and radially outward until it leaves through all circumferential parts of the impeller into the diffuser part of the casing. The fluid gains both velocity and pressure while passing through the impeller. The doughnut-shaped diffuser, or scroll, section of the casing decelerates the flow and further increases the pressure. It is important to note that the water is not pushed radially outward by centrifugal force (non-existent force), but rather by inertia, the natural tendency of an object to continue in a straight line (tangent to the radius) when traveling around circle. This can be compared to the way a spin-cycle works in a washing machine.

Description by Euler[edit]

A consequence of Newton’s second law of mechanics is the conservation of the angular momentum (or the “moment of momentum”) which is of fundamental significance to all turbomachines. Accordingly, the change of the angular momentum is equal to the sum of the external moments. Angular momentums ρ×Q×r×cu at inlet and outlet, an external torque M and friction moments due to shear stresses Mτ are acting on an impeller or a diffuser.

Since no pressure forces are created on cylindrical surfaces in the circumferential direction, it is possible to write Eq. (1.10) as:[4]

- (1.13)

Euler's pump equation[edit]

Based on Eq.(1.13) Euler developed the head pressure equation created by the impeller see Fig.2.2

- (1)

- (2)

In Eq. (2) the sum of 4 front element number call static pressure,the sum of last 2 element number call velocity pressure look carefully on the Fig 2.2 and the detail equation.

Ht theory head pressure ; g = between 9.78 and 9.82 m/s2 depending on latitude, conventional standard value of exactly 9.80665 m/s2 barycentric gravitational acceleration

u2=r2.ω the peripheral circumferential velocity vector

u1=r1.ω the inlet circumferential velocity vector

ω=2π.n angular velocity

w1 inlet relative velocity vector

w2 outlet relative velocity vector

c1 inlet absolute velocity vector

c2 outlet absolute velocity vector

Velocity Triangle[edit]

The color triangle formed by velocity vector u,c,w called 'velocity triangle'. This rule was helpful to detail Eq.(1) become Eq.(2) and wide explained how the pump works.

Fig 2.3 (a) shows triangle velocity of forward curved vanes impeller ; Fig 2.3 (b) shows triangle velocity of radial straight vanes impeller. It illustrates rather clearly energy added to the flow (shown in vector c) inversely change upon flow rate Q (shown in vector cm).

Efficiency factor[edit]

,

where:

- is the mechanics input power required (W)

- is the fluid density (kg/m3)

- is the standard acceleration of gravity (9.80665 m/s2)

- is the energy Head added to the flow (m)

- is the flow rate (m3/s)

- is the efficiency of the pump plant as a decimal

The head added by the pump () is a sum of the static lift, the head loss due to friction and any losses due to valves or pipe bends all expressed in metres of fluid. Power is more commonly expressed as kilowatts (103 W, kW) or horsepower. The value for the pump efficiency, , may be stated for the pump itself or as a combined efficiency of the pump and motor system.

Vertical centrifugal pumps[edit]

Vertical centrifugal pumps are also referred to as cantilever pumps. They utilize a unique shaft and bearing support configuration that allows the volute to hang in the sump while the bearings are outside the sump. This style of pump uses no stuffing box to seal the shaft but instead utilizes a 'throttle bushing'. A common application for this style of pump is in a parts washer.

Froth pumps[edit]

In the mineral industry, or in the extraction of oilsand, froth is generated to separate the rich minerals or bitumen from the sand and clays. Froth contains air that tends to block conventional pumps and cause loss of prime. Over history, industry has developed different ways to deal with this problem. In the pulp and paper industry holes are drilled in the impeller. Air escapes to the back of the impeller and a special expeller discharges the air back to the suction tank. The impeller may also feature special small vanes between the primary vanes called split vanes or secondary vanes. Some pumps may feature a large eye, an inducer or recirculation of pressurized froth from the pump discharge back to the suction to break the bubbles.[5]

Industrial Centrifugal Water Pumps

Multistage centrifugal pumps[edit]

A centrifugal pump containing two or more impellers is called a multistage centrifugal pump. The impellers may be mounted on the same shaft or on different shafts. At each stage, the fluid is directed to the center before making its way to the discharge on the outer diameter.

For higher pressures at the outlet, impellers can be connected in series. For higher flow output, impellers can be connected in parallel.

A common application of the multistage centrifugal pump is the boiler feedwater pump. For example, a 350 MW unit would require two feedpumps in parallel. Each feedpump is a multistage centrifugal pump producing 150 l/s at 21 MPa.

All energy transferred to the fluid is derived from the mechanical energy driving the impeller. This can be measured at isentropic compression, resulting in a slight temperature increase (in addition to the pressure increase).

Energy usage[edit]

The energy usage in a pumping installation is determined by the flow required, the height lifted and the length and friction characteristics of the pipeline.The power required to drive a pump (), is defined simply using SI units by:

where:

- is the input power required (W)

- is the fluid density (kg/m3)

- is the standard acceleration of gravity (9.80665 m/s2)

- is the energy Head added to the flow (m)

- is the flow rate (m3/s)

- is the efficiency of the pump plant as a decimal

Types Of Casing In Centrifugal Pump Pdf

The head added by the pump () is a sum of the static lift, the head loss due to friction and any losses due to valves or pipe bends all expressed in metres of fluid. Power is more commonly expressed as kilowatts (103 W, kW) or horsepower (hp = kW/0.746). The value for the pump efficiency, , may be stated for the pump itself or as a combined efficiency of the pump and motor system.

The energy usage is determined by multiplying the power requirement by the length of time the pump is operating.

Problems of centrifugal pumps[edit]

These are some difficulties faced in centrifugal pumps:[7]

- Cavitation—the net positive suction head (NPSH) of the system is too low for the selected pump

- Wear of the impeller—can be worsened by suspended solids

- Corrosion inside the pump caused by the fluid properties

- Overheating due to low flow

- Leakage along rotating shaft.

- Lack of prime—centrifugal pumps must be filled (with the fluid to be pumped) in order to operate

Centrifugal pumps for solids control[edit]

An oilfield solids control system needs many centrifugal pumps to sit on or in mud tanks. The types of centrifugal pumps used are sand pumps, submersible slurry pumps, shear pumps, and charging pumps. They are defined for their different functions, but their working principle is the same.

Magnetically coupled pumps[edit]

Magnetically coupled pumps, or magnetic drive pumps, vary from the traditional pumping style, as the motor is coupled to the pump by magnetic means rather than by a direct mechanical shaft. The pump works via a drive magnet, 'driving' the pump rotor, which is magnetically coupled to the primary shaft driven by the motor.[8] They are often used where leakage of the fluid pumped poses a great risk (e.g., aggressive fluid in the chemical or nuclear industry, or electric shock - garden fountains). They have no direct connection between the motor shaft and the impeller, so no gland is needed. There is no risk of leakage, unless the casing is broken. Since the pump shaft is not supported by bearings outside the pump's housing, support inside the pump is provided by bushings. The pump size of a magnetic drive pumps can go from few Watts power to a giant 1MW.

Pump Types And Operation Pdf

Priming[edit]

Most centrifugal pumps are not self-priming. In other words, the pump casing must be filled with liquid before the pump is started, or the pump will not be able to function. If the pump casing becomes filled with vapors or gases, the pump impeller becomes gas-bound and incapable of pumping. To ensure that a centrifugal pump remains primed and does not become gas-bound, most centrifugal pumps are located below the level of the source from which the pump is to take its suction. The same effect can be gained by supplying liquid to the pump suction under pressure supplied by another pump placed in the suction line. The process of filling the pump with liquid is called priming.

Self-priming centrifugal pump[edit]

In normal conditions, common centrifugal pumps are unable to evacuate the air from an inlet line leading to a fluid level whose geodetic altitude is below that of the pump. Self-priming pumps have to be capable of evacuating air (see Venting) from the pump suction line without any external auxiliary devices.

Centrifugal pumps with an internal suction stage such as water-jet pumps or side-channel pumps are also classified as self-priming pumps. Self-Priming centrifugal were invented in 1935. One of the first companies to market a self-priming centrifugal pump was American Marsh in 1938.

Centrifugal pumps that are not designed with an internal or external self-priming stage can only start to pump the fluid after the pump has initially been primed with the fluid. Sturdier but slower, their impellers are designed to move water, which is far denser than air, leaving them unable to operate when air is present.[9] In addition, a suction-side swing check valve or a vent valve must be fitted to prevent any siphon action and ensure that the fluid remains in the casing when the pump has been stopped. In self-priming centrifugal pumps with a separation chamber the fluid pumped and the entrained air bubbles are pumped into the separation chamber by the impeller action.

The air escapes through the pump discharge nozzle whilst the fluid drops back down and is once more entrained by the impeller. The suction line is thus continuously evacuated. The design required for such a self-priming feature has an adverse effect on pump efficiency. Also, the dimensions of the separating chamber are relatively large. For these reasons this solution is only adopted for small pumps, e.g. garden pumps. More frequently used types of self-priming pumps are side-channel and water-ring pumps. Another type of self-priming pump is a centrifugal pump with two casing chambers and an open impeller. This design is not only used for its self-priming capabilities but also for its degassing effects when pumping twophase mixtures (air/gas and liquid) for a short time in process engineering or when handling polluted fluids, for example, when draining water from construction pits.

This pump type operates without a foot valve and without an evacuation device on the suction side. The pump has to be primed with the fluid to be handled prior to commissioning. Two-phase mixture is pumped until the suction line has been evacuated and the fluid level has been pushed into the front suction intake chamber by atmospheric pressure. During normal pumping operation this pump works like an ordinary centrifugal pump.

See also[edit]

- Net positive suction head (NPSH)

- Specific speed (Ns or Nss)

References[edit]

- ^Shepard, Dennis G. (1956). Principles of Turbomachinery. Macmillan. ISBN0-471-85546-4. LCCN56002849.

- ^'Sprayer Pump Types, Costs, and Specifications'. Sprayer Supplies. 2018-10-13. Retrieved 2018-11-21.

- ^Reti, Ladislao; Di Giorgio Martini, Francesco (Summer 1963). 'Francesco di Giorgio (Armani) Martini's Treatise on Engineering and Its Plagiarists'. Technology and Culture. 4 (3): 287–298 (290). doi:10.2307/3100858.

- ^Gülich, Johann Friedrich (2010). Centrifugal Pumps (2nd ed.). ISBN978-3-642-12823-3.

- ^Baha Abulnaga (2004). Pumping Oilsand Froth(PDF). 21st International Pump Users Symposium, Baltimore, Maryland. Published by Texas A&M University, Texas, USA.

- ^Moniz, Paresh Girdhar, Octo (2004). Practical centrifugal pumps design, operation and maintenance (1. publ. ed.). Oxford: Newnes. p. 13. ISBN0750662735. Retrieved 3 April 2015.

- ^Larry Bachus, Angle Custodio (2003). Know and understand centrifugal pumps. Elsevier Ltd. ISBN1856174093.

- ^Pump Handbook:third edition

- ^'How do self-priming pumps work?'. Pump Sales Direct Blog. 2018-05-11. Retrieved 2018-05-11.

Sources[edit]

External links[edit]

- Minimum Thermal Flow in Centrifugal Pumps - Chemical Engineering Site

| Look up Centrifugal pump in Wiktionary, the free dictionary. |

| Wikimedia Commons has media related to Centrifugal pumps. |

In the previous article we learned about the various characteristics, main parts and special features of the rotary pumps. In this article we will learn about the working of various types of rotary pumps, i.e. screw, lobe, gear and vane pump. We will also learn how is the working of screw pump different from that of other types of pumps.

Working of Gear, Vane or Lobe Pump

Though the construction, shape and design of gear, vane and globe pumps are a bit different , they fall under the same category of rotary pumps. The working of all these pumps are based on the same principle, i.e pumping of the liquid with the help of rotating elements. The rotating elements can be gears, screws or vanes. We will understand the basic principle of all these pumps by taking the working system of gear pumps into consideration.

A gear pumps rotating assembly consists of two gears, a driving gear and a driven gear. Pumping in a gear pump takes place when the driving gear meshes with the driven gear to form cavities that moves the fluid.The cavities are the clearances between the gears or lobes and the body of the pump. The mating surfaces of the gears’ mesh provide continuous sealing between the the inlet and outlet ports.

As the rotation of the pump continues, the movement of the cavities progresses, thus moving the fluid along the way. After some time, a point is reached where the seal between the captured fluid and the outlet part of the pump is broken. At this point of time the vanes, gears or lobes, forces the volume of the captured fluid out of the pump. A continuous cycle takes place due to the simultaneously opening of new cavities at the inlet port. This leads to a continuous flow of liquid though the suction and discharge ports.

Working Of Screw Pump

Screw pumps also falls in the category of rotary pumps and have the same mechanism and principle. Screw pumps are the only type of pumps which are different from other rotary displacement pumps because of the axial flow of the fluid through their pumping elements.The fluid in screw pumps moves between the screw threads and is displaced axially as the screws rotate and mesh.

Due to the axial flow pattern and low internal velocities,the screw pumps have certain advantages in applications where churning and agitation of fluid is highly objectionable or not allowed.The inter-meshing of the screw threads on the rotors and the very fine clearances of the surrounding housing creates a seal between the pumps inlet and outlet.

Due to the rotation of the screws and the movement of fine clearances, pockets are formed in the helices of the screw.As the screw moves the pockets also move axially and act similar to a piston moving in one direction, while the fluid is moved axially from inlet to outlet.

References/Image Credits

Pump Handbook- 4th Edition By Tata McGraw Hill

Marine Auxiliary Machinery, 7th Edition, 1995 by McGeorge